Everyone’s favourite treat is getting a sweet, sustainable, and healthy upgrade. Photo credit: Monique Carrati via Unsplash

Chocolate—universally loved for its smooth texture and sweet flavours—can be traced back over 4,000 years to the Olmec Civilisation in Latin America. In recent history, however, it has been Switzerland that has made a name in the world of chocolate, with big brands, such as Lindt and Toblerone. Earlier this year, a team of scientists at Zurich’s Federal Institute of Technology led by Kim Mishra developed a new recipe for chocolate, utilising the whole cocoa fruit as opposed to just the cocoa beans. This breakthrough in chocolate science could lead to a healthier, more sustainable version of one of the world’s favourite treats.

This leaves the new chocolate with up to 30% less saturated fat, and nearly 20% more fibre, producing a potentially healthier product.

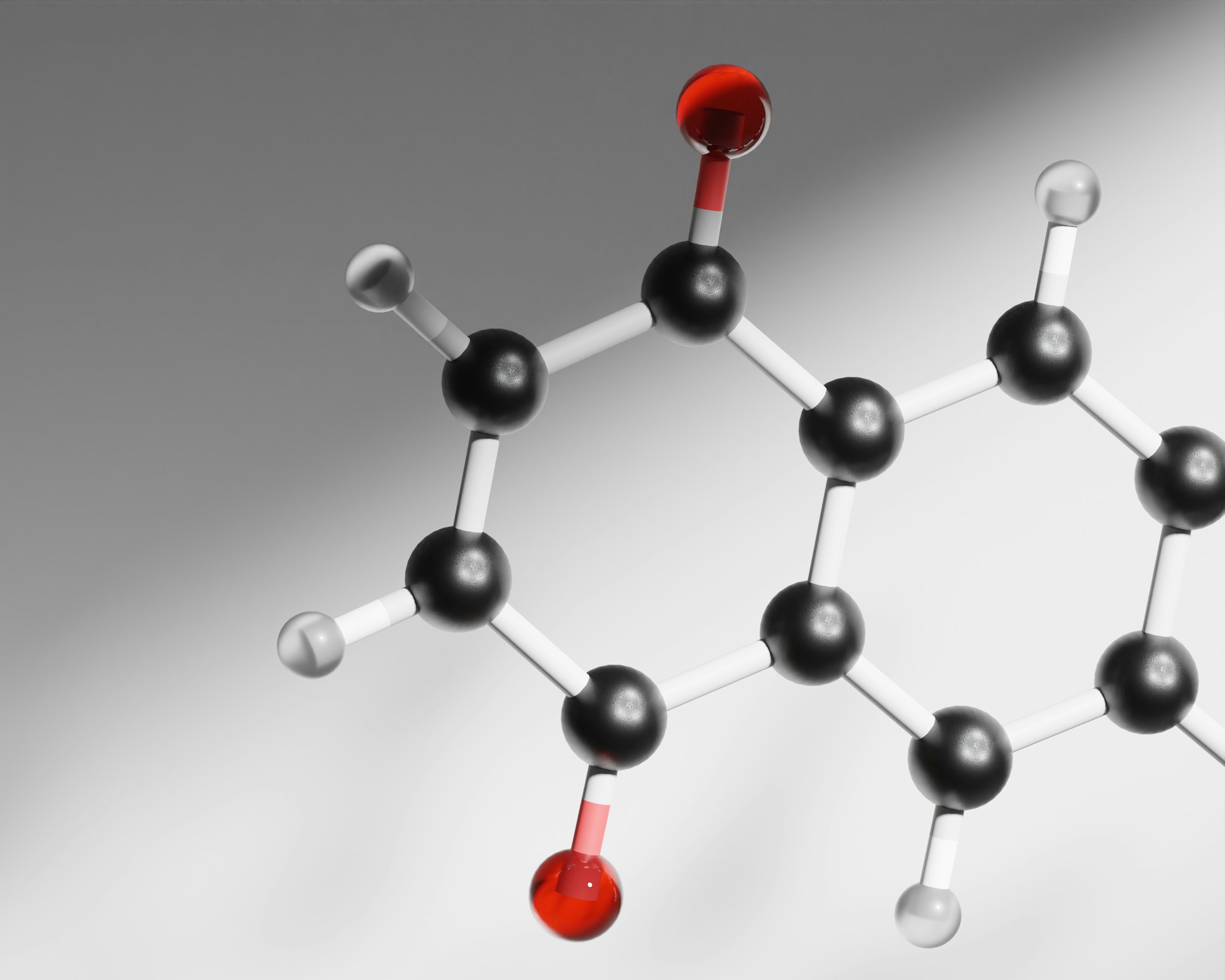

In traditional chocolate production, the cocoa beans are harvested from the fruit before being fermented, dried, roasted, and combined with other ingredients, such as milk and sugar. In the 19th century, Swiss chocolatier Rudolf Lindt accidentally invented a new step to this process known as “conching”, where the warm cocoa is rolled to make it smoother and reduce its acidity, when he left his mixer going overnight. Now, Switzerland plays a pioneering role in chocolate production once again by making use of the previously discarded parts of the cocoa fruit, such as the pulp and husk. The key ingredient, however, is the sweet juice of the cocoa fruit used to replace refined sugar. The juice contains up to 14% sugar, which can then be distilled into a concentrated syrup that is combined with the rest of the fruit, to add sweetness to the chocolate. This leaves the new chocolate with up to 30% less saturated fat, and nearly 20% more fibre, producing a potentially healthier product. With the links between refined sugar, fats, and health conditions, such as cardiovascular disease and diabetes, this could be revolutionary for both the chocolate industry, and its consumers. Companies such as Lindt have already started to use parts of the cocoa fruit in production, but this new method is the first to eliminate the need for sugar completely, and the Zurich Federal Institute of Technology have filed for a patent on their novel recipe.

…it tasted like rich, fruity dark chocolate, similar to those from South America.

Without added sugar, it brings into question whether this healthy alternative will really taste like chocolate at all. To address this, the team in Zurich had chocolate tasters come in and give it a try, with reports that it tasted like rich, fruity dark chocolate, similar to those from South America. In manufacture, the juice from the cocoa fruit is combined with other parts of the fruit into a pulp, causing some issues with chocolate clumping— a problem not experienced when refined sugar is used. Using too much cocoa juice for sweetness gave a clumpy, unenjoyable texture. The need to balance texture and sweetness meant the team landed on a dark chocolate recipe.

Using the whole fruit also means more chocolate can be created from less land and less water.

When it comes to chocolate, however, there are far more components than just the taste. Cocoa farming and the chocolate industry have a long history of exploitation, child labour, and unsustainable practices. Nowadays, fair trade laws are attempting to tackle these issues, and the industry is more regulated, but that is only one step in the right direction. The use of the whole fruit in the chocolate making process not only makes it more sustainable, with less waste produced, but also allows more of the money to go directly back to the farmers, who can begin to process parts of the fruit themselves. Using the whole fruit also means more chocolate can be created from less land and less water. Currently, chocolate ranks alongside meat as one of the most greenhouse gas emitting foods per kilogram, with a 2019 study at the University of Edinburgh estimating a 200g carbon dioxide emission per bar of chocolate. These emissions come largely from deforestation used to clear land in order to grow the cocoa fruit, alongside methane emissions from cows used to source the milk needed for production. By using less land per kilo of chocolate, some of this deforestation and land clearing can potentially be reduced.

Currently, chocolate ranks alongside meat as one of the most greenhouse gas emitting foods per kilogram…

The future of chocolate is being invented today. The more healthy, more sustainable, whole food approach to chocolate making still needs to be adapted for large scale production. We are not likely to see a full cocoa fruit bar on our supermarket shelves soon, but progress is on the way. Change needs to start from the bottom up, with the farmers adapting their practices to allow for large-scale drying of the fruit, before manufacturers can then follow suit. One day soon, though, you might be able to sit down and enjoy your chocolate bar as a healthier, more ethical, snack.