Scientists have created a remarkable novel material through molecular interactions. Photo credit: Ayush Kumar via Unsplash

Published in Science, earlier this year, researchers from Northwestern University have developed an ultra-strong material dubbed “molecular chain mail.” This material can already be synthesised on a large scale and easily processed, enabling its characterisation and straightforward incorporation into composite fibres to enhance strength.

Its strength comes from interlocking metal rings, forming a flexible yet strong mesh.

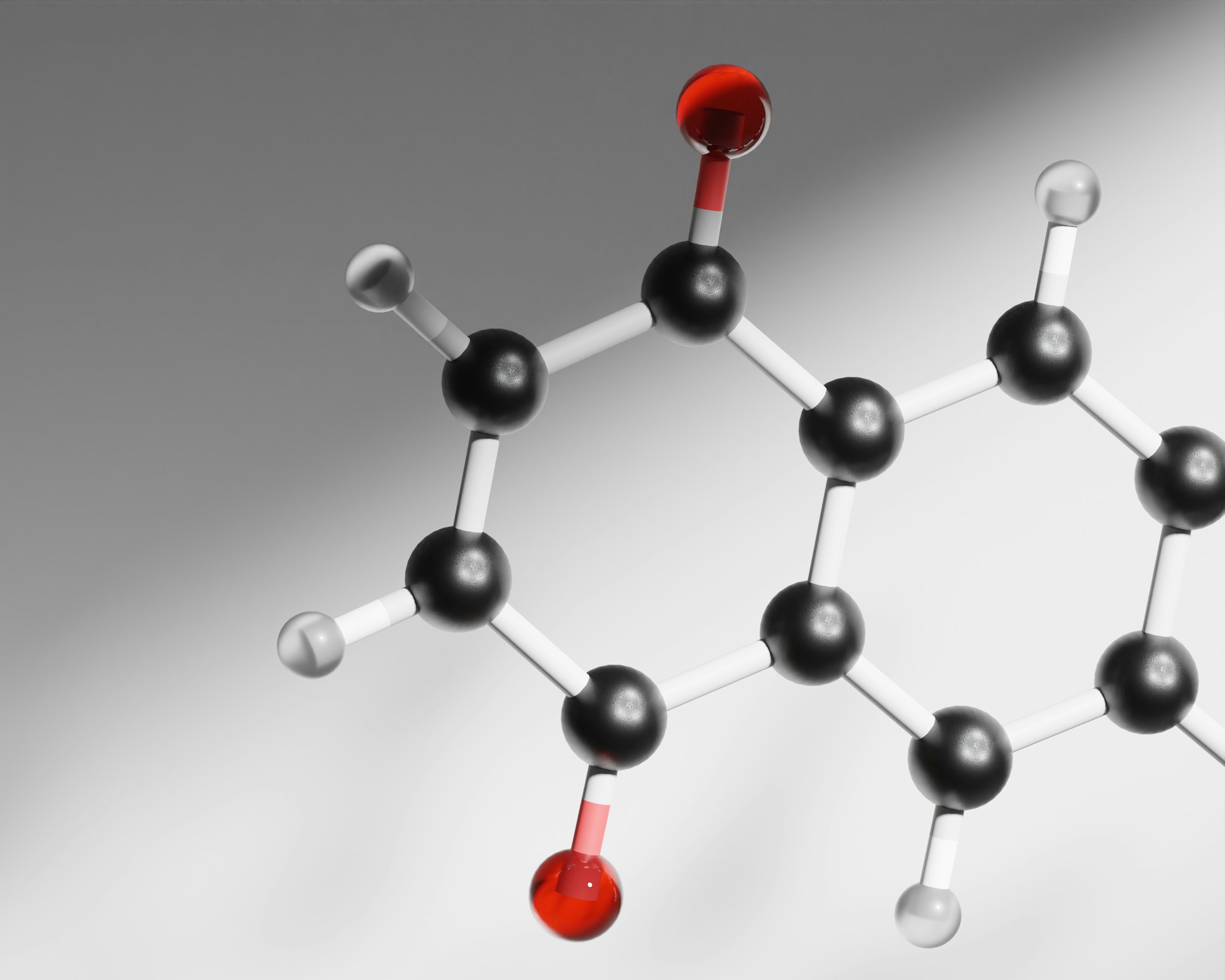

Chain mail has been used widely for centuries as armour, protecting soldiers from slashing and stabbing weapons. Its strength comes from interlocking metal rings, forming a flexible yet strong mesh. However, it struggled to protect the wearer against pointed weapons and projectiles, which could pierce the gaps between the rings. To overcome this, metal plates were used instead, but these were heavy and, as firearms developed, became useless. By World War II, chemical manufacturing giant, DuPont, had developed Nylon, polymers containing amide linkages between the monomer units (Figure 1). The amide linkages form hydrogen bonds between the polymer chains, an intermolecular attraction between the hydrogens of the amide linkage (N–H) and the nitrogen or oxygens of other polymer chains, providing additional strength. Nylon fibres were used as body armour during WW2 in flak jackets to protect against shrapnel, the fragments that fly through the air after an explosion. However, they remained ineffective against high-velocity bullets. In 1965, DuPont researcher Stephanie Kwolek synthesised Kevlar, which is still used in modern body armour. Kevlar is structurally similar to Nylon but even stronger due to its chemical makeup of flat aromatic monomer units that can pack closer together and form stronger interactions between the polymer chains, meaning that more energy is required to break them apart (Figure 2).

Earlier this year, Professor William Dichtel’s research group drew inspiration from historical armour by designing a two-dimensional polymer with a molecular chain mail structure, the next chapter in the story of modern armour. Just as metal rings interlock in chain mail, the monomer units in this polymer interlock, creating a mechanical bond at each repeating unit. This results in a staggering one million mechanical bonds per square micrometre, a record for the highest density of mechanical bonds. This unique characteristic gives the material exceptional strength properties. Unlike traditional chain mail, the molecular gaps in this material are much smaller, making it a highly promising candidate for advanced, durable materials. Its potential application is not limited to next-generation body armour alone but also materials for aerospace and automotive vehicles, structural engineering, and biotechnology, amongst many more.

…one million mechanical bonds per square micrometre, a record for the highest density of mechanical bonds.

At a press conference, Dichtel explained how the material works, ‘It’s similar to chainmail in that it cannot easily rip, each mechanical bond has some freedom to slide around. If you pull it, the force is dissipated in multiple directions. And if you try to tear it apart, you would have to break it in many different places.’ Forming a mechanical bond is not easy, as the molecular units need to be arranged in a specific manner. The lead researcher, Madison Bardot, devised a new strategy to prepare such a unique structure. This involved using a solid-state polymerisation technique where the X-shaped monomers pack together in a layered 2D crystal structure by forming hydrogen bonds so that they are ready to interlock (Figure 2). Next, a chemical known as a dialkyldichlorosilane (SiMe2Cl2) diffuses into the crystals. It reacts selectively at each hydrogen bond linkage to form specific covalent siloxane linkages, locking the interlocked polymer chains (Figure 2).

One of the key advantages of this elegant technique is that it employs simple and readily available monomers, producing the final material in 75% yield. This has already been scaled up to over 10 g, which is a remarkable achievement, as most interlocked molecule syntheses are limited to only a few milligrams. Additionally, the material is soluble in common solvents, which facilitates purification and characterisation.

In collaboration with researchers from Duke University, the material was incorporated into composite fibres with Ultem, a polymer in the same family as Kevlar. Even at just 2.5% weight loading, wherein 100 g of material contains 2.5 g of the molecular chainmail and 97.5 g of Ultem, the molecular chainmail significantly enhanced the material’s mechanical strength. This is promising for potential applications in protective gear, aerospace materials, and other high-performance composites.

…potential applications in protective gear, aerospace materials, and other high-performance composites.

The research team dedicated their work Sir Fraser Stoddart, who passed away on December 30, 2024. Dichtel was a former postdoctoral researcher in Stoddart’s lab and later a colleague at Northwestern University. Stoddart was awarded the Nobel Prize in Chemistry in 2016 for his groundbreaking work on the synthesis of mechanically interlocked molecules, which laid the foundation for this remarkable new material.